Electric Motors is at the heart of technology and many appliances we use today. Society would not be able to function without them.

What is it?

History:

“The invention of the electric motor is the result of a number of inventions and discoveries in the of electricity during the 18th and 19th centuries. While ‘electricity’ and ‘magnetism ’some of their properties had been known for many years, how to use them to produce mechanical motion was not. Several key discoveries were critical to the invention of the electric motor. These discoveries included the discovery of electricity, the battery, and the principle of electromagnetism.” (http://web.a.ebscohost.com/ehost/detail/detail?vid=6&sid=c3a792b4-0e8b-4b72-933d-f61e3b5b510c%40sessionmgr4003&hid=4101&bdata=JnNpdGU9ZWhvc3QtbGl2ZQ%3d%3d#AN=EJ706293&db=eric).

“The invention of the electric motor is the result of a number of inventions and discoveries in the of electricity during the 18th and 19th centuries. While ‘electricity’ and ‘magnetism ’some of their properties had been known for many years, how to use them to produce mechanical motion was not. Several key discoveries were critical to the invention of the electric motor. These discoveries included the discovery of electricity, the battery, and the principle of electromagnetism.” (http://web.a.ebscohost.com/ehost/detail/detail?vid=6&sid=c3a792b4-0e8b-4b72-933d-f61e3b5b510c%40sessionmgr4003&hid=4101&bdata=JnNpdGU9ZWhvc3QtbGl2ZQ%3d%3d#AN=EJ706293&db=eric). |

| Micheal Faraday |

“The invention of the electric motor closely followed the realization that an electric current produces a magnetic field. In 1821, a year after Denmark's Hans Christian Oersted (1777–1851) discovered this phenomenon, Michael Faraday (1791–1867) of Great Britain constructed an apparatus that is often described as the first electric motor...In Italy, Salvatore dal Negro built in 1830 an electric motor that produced a reciprocating motion. Another linear motor was built in France by Paul Fromont (1815–1865). Both Fromont and dal Negro used additional mechanical devices to impart a rotary motion. In the United States, Joseph Henry (1797– 1878) built an experimental motor in the 1829, as did Charles Grafton Page (1812–1868) and Thomas Davenport (1802–1851) a few years later.” http://online.infobase.com/HRC/Search/Details/283064?q=electric%20motors

|

| Thomas Davenport |

|

| An Early Davenport Motor |

Davenport’s motor eventually made way for the first trolley. The motor was able to “run a model trolley on a circular track and [perform] other tasks. The trolley later turne dout to be the first importnat application of electric power...Rudimentary full sized electric trolleys were finally built 30 years after Davenport’s death in the 1850’s” (http://www.edisontechcenter.org/electricmotors.html).

However, these earlier motors do not resemble anything like a modern electric motor and were more useful for demonstrations. These motors “created spinning disks or levers that rocked back and forth. These devices could not do any work for humankind but were important for leading the way to better motors in the future.” (http://www.edisontechcenter.org/electricmotors.html).

|

| Zenobe Theophile Gramme |

“In 1873, the first commercially successful DC motor was demonstrated in Vienna at an exhibition by Zenobe Theophile Gramme, a Belgian electrical engineer. Gramme also introduced an armature that improved the efficiency of early electric motors and generators.” (http://www.worldbookonline.com/student/article?id=ar176700&st=electric+motor#tab=homepage).

|

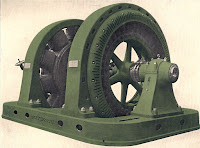

| Gramme motors |

“For many years, however, the incentive to create better electric motors was limited, for they were of little practical use. The main problem was that the motors lacked an effective, inexpensive source of electricity. For much of the 19th century, batteries were the primary source of electricity, and the energy they supplied was more than 20 times more expensive than the energy provided by contemporary steam engines. Electric motors became an economical source of energy only after improvements in electrical generators made possible a large-scale expansion of electrical supply. Expanding demand was equally important, for the installation of early generators was motivated by the introduction of the first significant commercial application of electric power, arc lighting. Once electrical systems for arc lights were in place, the widespread use of electric motors became an attractive proposition to early power suppliers, for the motors were likely to be used at times and places where electrical demands for lighting were low...

|

| Edison's Electric Stencil-Cutting Pen |

By the 1880s improved electric motors were being used for a variety of purposes… [and] in 1880 Thomas Edison began to market a stencil-cutting pen powered by an electric motor, the first one to be sold in large volume. Electricmotors were even beginning to show up in American homes, where they were used to power sewing machines. In 1887, 15 American manufacturers collectively produced 10,000 motors....

|

| Electric Motor Machinery in Factories (Sewing Machines in clothing factory) |

Basic Parts of an Electric Motor:

The armature is the “rotating part of an electric machine (as a generator or motor) which consists essentially of coils of wire around a metal core and in which electric current is induced or in which the input current interacts with a magnetic field to produce torque.” (http://www.merriam-webster.com/dictionary/armature).

According to http://www.worldbookonline.com/student/article?id=ar176700&st=electric+motor#tab=homepage, |

| Diagram of Electric Motor With Parts |

The brushes are wires that are connected to the sides of the commutator, carrying the electrical current to the battery or power source.

The axle allows electricity to flow into the armature and connects the armature to the commutator.

The field magnet is a “permanent magnet that is placed near the armature...the field magnet will cause the armature to spin.” (http://www.tech-faq.com/how-do-electric-motors-work.html).

Types of Motors:

There are two main types of motors: DC or Direct Current and AC or Alternating Current.

The Invention of the AC Motor:

|

| Simple AC Motor |

Differences in AC and DC motors:

“While both A.C. and D.C. motors serve the same function of converting electrical energy into mechanical energy, they are powered, constructed and controlled differently. The most basic difference is the power source. A.C. motors are powered from alternating current (A.C.) while D.C. motors are powered from direct current (D.C.), such as batteries, D.C. power supplies or an AC-to-DC power converter. D.C wound field motors are constructed with brushes and a commutator, which add to the maintenance, limit the speed and usually reduce the life expectancy of brushed D.C. motors. A.C. induction motors do not use brushes; they are very rugged and have long life expectancies. The final basic difference is speed control. The speed of a D.C. motor is controlled by varying the armature winding’s current while the speed of an A.C. motor is controlled by varying the frequency, which is commonly done with an adjustable frequency drive control.” (http://www.ohioelectricmotors.com/2015/07/what-is-the-difference-between-an-ac-motor-and-a-dc-motor/).

|

| Simple DC Motor |

Advantages and Disadvantages of DC and AC motors:

“Ac motor tend to be smaller, more reliable, and less expensive but run at a fixed speed that is determined by the line frequency. On the other hand DC motor have speed-control capability,which means that speed, torque, and even direction of rotation can be changed at any time to meet new conditions.

Also, smaller DC motors commonly operate at lower voltages (for example, a 12-V disk drive motor), which makes them easier to interface with control electronics.Disadvantage of dc motor is the mandatory use of brush and slip ring arrangement in DC motor has its own limitation.” (http://eblogbd.com/basic-construction-difference-between-ac-and-dc-motor/).

What are they useful for?

“ DC motors are used in large applications, the use of drives are very necessary for the smooth running and operating of these motors. The DC motor drives are used mainly for good speed regulation, frequent starting, braking and reversing.” (http://www.electrical4u.com/dc-motor-drives/)

-Cars

-Drills

-Sewing Machines

-Etc.

“AC Motors are primarily used in domestic applications due to their relatively low manufacturing costs, and durability, but are also widely used in industrial applications.

What Applications are AC Motors used for?

AC Motors can be found in numerous home appliances and applications, including:

- Clocks

- Power tools

- Disk drives

- Washing Machines and other Home Appliances

- Fans

- Hair Dryer

- Hair Dryer

They can also be found in industrial applications:

- Pumps

- Blowers

- Conveyors

- Compressors” (http://www.anaheimautomation.com/manuals/forms/ac-motor-guide.php#sthash.yoTWyDMM.dpuf)

DC:

“The permanent magnet motor uses a magnet to supply field flux. Permanent magnet DC motors have excellent starting torque capability with good speed regulation. A disadvantage of permanent magnet DC motors is they are limited to the amount of load they can drive.These

motors can be found on low horsepower applications.”

|

| Shunt Motor Diagram |

|

| Compound Motor Diagram |

DC motors are commonly used in robotics.

AC Motors:

|

| Induction Motor in a 3D Printer |

|

| Synchronous Motor |

|

| Example of an Industrial Motor |

How Electric Motors Work:

Basic DC Motor:

“The operation of an electric motor is based on three main principles: (1) An electric current produces a magnetic field; (2) the direction of a current in an electromagnet determines the location of the magnet's poles; and (3) magnetic poles attract or repel each other.” (http://www.worldbookonline.com/student/article?id=ar176700&st=electric+motor#tab=homepage).

An electric current from a power source travels through a wire in a magnetic field, creating the field magnet. There are two bar magnets labeled as “north” and “south.” The North end will attract one side of the magnet and repel the other. The South end will do the opposite, attracting the side the North repels and repelling the side that the North attracts.(http://electronics.howstuffworks.com/motor1.htm). The brushes are connected to the commutator. The brushes carry an external electric current that, when in contact with the commutator, carries the electric current from the brush and sends it through the axle and ultimately to the armature. “When the magnetic poles thereby created in the armature are next to like poles of the field magnet, the armature rotates a half turn, past one of the gaps separating the rings [of the commutator].” http://www.worldbookonline.com/student/article?id=ar176700&st=electric+motor#tab=homepage.

Once the second ring of the commutator comes into contact with the other brush, carrying the electric current to the armature, reversing the direction of the current. The current is now reversed, also switching the magnetic attraction forces causing the “Like poles of the field magnet and the armature are once again opposite each other,” causing the rotational motion. One of the brushes is connected to the power source, causing all of the electricity to flow back to the power source.

Basic AC Motor:

“In an AC motor, there's a ring of electromagnets arranged around the outside (making up the stator), which are designed to produce a rotating magnetic field. Inside the stator, there's a solid metal axle, a loop of wire, a coil, a squirrel cage made of metal bars and interconnections (like the rotating cages people sometimes get to amuse pet mice), or some other freely rotating metal part that can conduct electricity. Unlike in a DC motor, where you send power to the inner rotor, in an AC motor you send power to the outer coils that make up the stator. The coils are energized in pairs, in sequence, producing a magnetic field that rotates around the outside of the motor.

...The rotor, suspended inside the magnetic field, is an electrical conductor. The magnetic field is constantly changing (because it's rotating) so, according to the laws of electromagnetism, the magnetic field produces (or induces...) an electric current inside the rotor. If the conductor is a ring or a wire, the current flows around it in a loop. If the conductor is simply a solid piece of metal, eddy currents [a localized electric current induced in a conductor by a varying magnetic field] swirl around it instead. Either way, the induced current produces its own magnetic field and, according to another law of electromagnetism (Lenz's law) tries to stop whatever it is that causes it—the rotating magnetic field—by rotating as well. (You can think of the rotor frantically trying to "catch up" with the rotating magnetic field in an effort to eliminate the difference in motion between them.) Electromagnetic induction is the key to why a motor like this spins—and that's why it's called an induction motor.” (http://www.explainthatstuff.com/induction-motors.html).

...The rotor, suspended inside the magnetic field, is an electrical conductor. The magnetic field is constantly changing (because it's rotating) so, according to the laws of electromagnetism, the magnetic field produces (or induces...) an electric current inside the rotor. If the conductor is a ring or a wire, the current flows around it in a loop. If the conductor is simply a solid piece of metal, eddy currents [a localized electric current induced in a conductor by a varying magnetic field] swirl around it instead. Either way, the induced current produces its own magnetic field and, according to another law of electromagnetism (Lenz's law) tries to stop whatever it is that causes it—the rotating magnetic field—by rotating as well. (You can think of the rotor frantically trying to "catch up" with the rotating magnetic field in an effort to eliminate the difference in motion between them.) Electromagnetic induction is the key to why a motor like this spins—and that's why it's called an induction motor.” (http://www.explainthatstuff.com/induction-motors.html).

Sources:

http://www.ohioelectricmotors.com/2015/07/what-is-the-difference-between-an-ac-motor-and-a-dc-motor/

http://electrical-engineering-portal.com/4-types-of-dc-motors-and-their-characteristics

No comments:

Post a Comment